Navigation

Anti-loosening fastener technology: simple production process, low cost, high strength, can be used in harsh environments

As soon as it is ready, please send us the CI and PL in Excel format.

Also, send us the quality certificates and photos of the materials

Threaded fasteners are the most commonly used standard parts in various mechanical equipment.

Threaded fasteners are indispensable in both production and life. Threaded connections are also the most commonly used form of various connection fastening methods, and are used in various fields that require connection fastening of separated parts.

Tooth type refers to the geometric shape of the thread. There are two main types of existing thread tooth section styles: triangular and trapezoidal. Internal and external threads with the same cross-sectional shape mesh with each other, and transmit force through the thread teeth to play the role of fastening or transmission.

However, the main disadvantages of these two types of threads are:

1)tall teeth and low material utilization;

2) serious stress concentration at the tooth root, which weakens the thread strength;

3) poor anti-loosening performance of the thread, requiring additional anti-loosening;

4) thread tooth section shape accuracy, high requirements, high manufacturing costs when using difficult-to-machine materials;

5) When the internal and external teeth are in direct contact during thread engagement, they are subject to comprehensive effects such as friction, bending, and shearing, especially the first ring thread is subject to maximum force, and the thread teeth are easily damaged.

Anti-loosening technology of threaded fasteners is an important topic in mechanical design and manufacturing, because the threaded connection is prone to loosening after being subjected to vibration, impact, or long-term use, thus affecting the normal operation and safety of the equipment.

The current anti-loosening fastener technology mainly includes: fastening, nuts, Japanese nuts, Down's bolts, conical fitting nuts, etc. The use effect is very good and it is widely used in many fields. But these technologies have defects such as high cost, difficult processing, weakened bearing capacity, large volume and large weight.

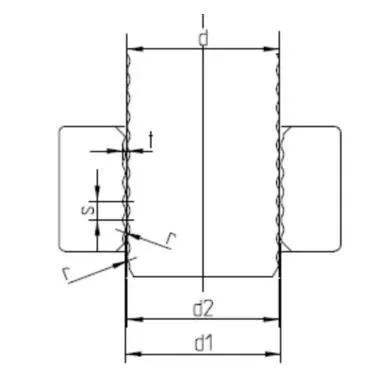

A brand-new fastening technology has been developed: large bearing capacity, anti-loosening, small volume, light weight, and the key is simple production process and low cost. Therefore, the application field is very wide, and it can be used in the demanding aerospace field. The invention provides a thin-walled elastic sleeve structure of a shallow arc thread pair and a fastening working method thereof. The inner and outer threads are made according to the same pitch and circular arc tooth section. A certain gap is designed between the tooth top and the tooth root, and a thin-walled elastic sleeve is accommodated between the gaps. The force is transmitted through the middle thin-walled elastic sleeve to realize the fastening effect or transmission.

This technology breaks through the traditional thread structure. After practice, the fastener produced according to this structure has high strength, good anti-loosening performance, light weight, low production cost, wide application of materials and high reliability, especially the elastic sleeve can be replaced to prolong the life of the fastener.

This technology is especially suitable for occasions that require high anti-loosening performance of fasteners, occasions that require high-strength fasteners, occasions that require lightweight fasteners, and especially suitable for occasions that require resistance to harsh environments such as severe temperature changes, as well as occasions that require the use of notch sensitivity and high materials.

As soon as it is ready, please send us the CI and PL in Excel format.

Also, send us the quality certificates and photos of the materials

Threaded fasteners are the most commonly used standard parts in various mechanical equipment.

Threaded fasteners are indispensable in both production and life. Threaded connections are also the most commonly used form of various connection fastening methods, and are used in various fields that require connection fastening of separated parts.

Tooth type refers to the geometric shape of the thread. There are two main types of existing thread tooth section styles: triangular and trapezoidal. Internal and external threads with the same cross-sectional shape mesh with each other, and transmit force through the thread teeth to play the role of fastening or transmission.

However, the main disadvantages of these two types of threads are:

1)tall teeth and low material utilization;

2) serious stress concentration at the tooth root, which weakens the thread strength;

3) poor anti-loosening performance of the thread, requiring additional anti-loosening;

4) thread tooth section shape accuracy, high requirements, high manufacturing costs when using difficult-to-machine materials;

5) When the internal and external teeth are in direct contact during thread engagement, they are subject to comprehensive effects such as friction, bending, and shearing, especially the first ring thread is subject to maximum force, and the thread teeth are easily damaged.

Anti-loosening technology of threaded fasteners is an important topic in mechanical design and manufacturing, because the threaded connection is prone to loosening after being subjected to vibration, impact, or long-term use, thus affecting the normal operation and safety of the equipment.

The current anti-loosening fastener technology mainly includes: fastening, nuts, Japanese nuts, Down's bolts, conical fitting nuts, etc. The use effect is very good and it is widely used in many fields. But these technologies have defects such as high cost, difficult processing, weakened bearing capacity, large volume and large weight.

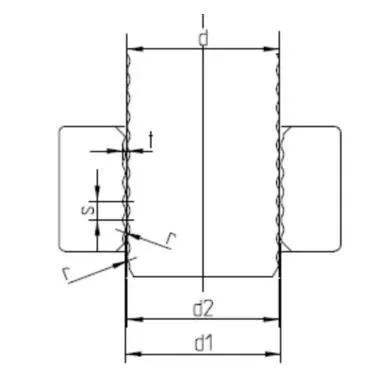

A brand-new fastening technology has been developed: large bearing capacity, anti-loosening, small volume, light weight, and the key is simple production process and low cost. Therefore, the application field is very wide, and it can be used in the demanding aerospace field. The invention provides a thin-walled elastic sleeve structure of a shallow arc thread pair and a fastening working method thereof. The inner and outer threads are made according to the same pitch and circular arc tooth section. A certain gap is designed between the tooth top and the tooth root, and a thin-walled elastic sleeve is accommodated between the gaps. The force is transmitted through the middle thin-walled elastic sleeve to realize the fastening effect or transmission.

This technology breaks through the traditional thread structure. After practice, the fastener produced according to this structure has high strength, good anti-loosening performance, light weight, low production cost, wide application of materials and high reliability, especially the elastic sleeve can be replaced to prolong the life of the fastener.

This technology is especially suitable for occasions that require high anti-loosening performance of fasteners, occasions that require high-strength fasteners, occasions that require lightweight fasteners, and especially suitable for occasions that require resistance to harsh environments such as severe temperature changes, as well as occasions that require the use of notch sensitivity and high materials.