Navigation

Summary of Fastener Corrosion Resistance

Fasteners play a vital role in industrial systems, but their small size often leads to their being overlooked. When selecting fasteners, in addition to specifications, the main considerations are appearance (color) and corrosion resistance. This article summarizes common surface treatment processes and the differences in corrosion resistance among materials.

Part.1 Material selection

There are many material options for fasteners. Stainless steel has good inherent corrosion resistance, commonly known as SUS304, SUS316which withstands neutral salt spray for 48-96 hours, while SUS410 stainless steel screws withstand neutral salt spray for about 20 hours.

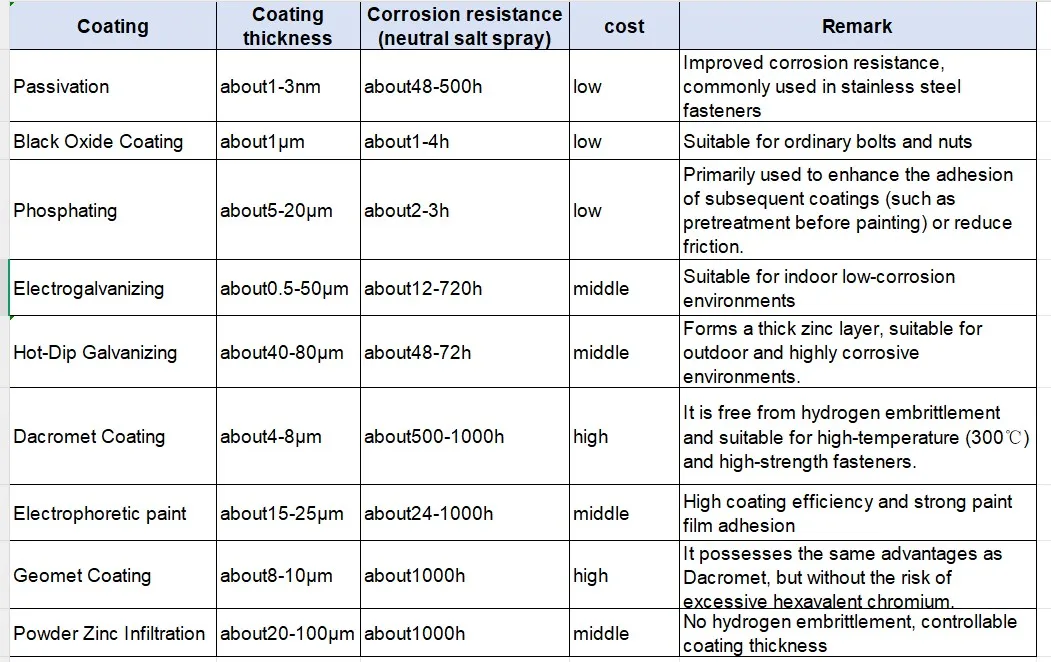

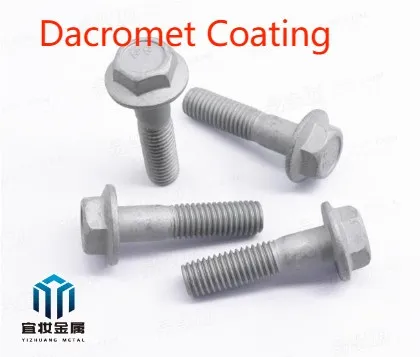

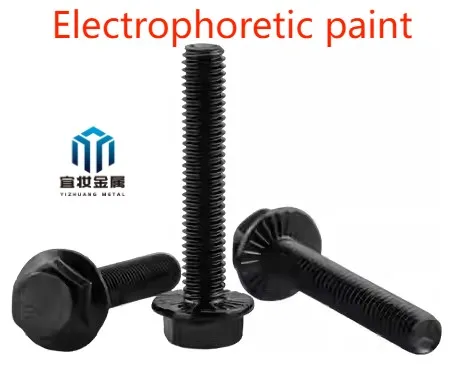

Part.2 Surface treatment

|

|

|

|

|

|

|

|

Fasteners play a vital role in industrial systems, but their small size often leads to their being overlooked. When selecting fasteners, in addition to specifications, the main considerations are appearance (color) and corrosion resistance. This article summarizes common surface treatment processes and the differences in corrosion resistance among materials.

Part.1 Material selection

There are many material options for fasteners. Stainless steel has good inherent corrosion resistance, commonly known as SUS304, SUS316which withstands neutral salt spray for 48-96 hours, while SUS410 stainless steel screws withstand neutral salt spray for about 20 hours.

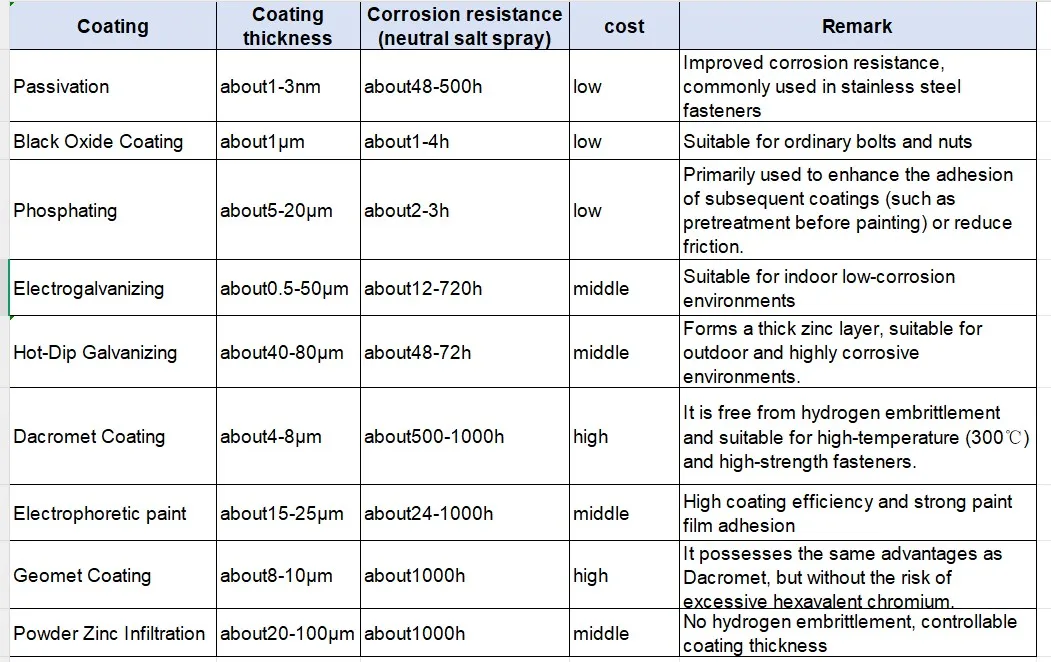

Part.2 Surface treatment

|

|

|

|

|

|

|

|