Navigation

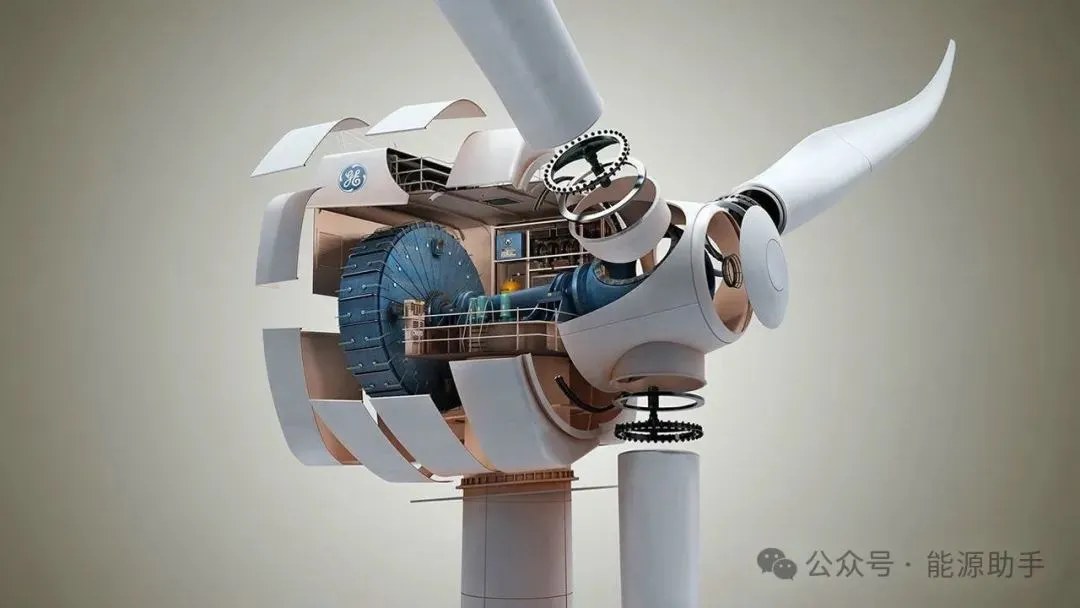

What fasteners are there in wind turbines?

Fasteners in wind turbines mainly include bolts, nuts, washers and so on. These fasteners play roles in connecting, fastening and supporting various components of wind turbines.

The following are some common types of fasteners: Bolts: Bolts are one of the most commonly used fasteners in wind turbines and are used to connect components such as blades, towers, and nacelles. Bolts usually need to possess properties like high strength, anti-fatigue and corrosion resistance to ensure the safe operation of wind turbines in harsh environments.

Nuts: Nuts are used in conjunction with bolts to fasten connected components.

In wind turbines, nuts usually need to have functions like anti-loosening and self-locking to prevent bolts from loosening under the influence of vibration and wind force.

Washers: Washers are usually used to increase the contact area of bolt connections, disperse pressure and prevent the wear of component surfaces.

In wind turbines, washers can also play roles such as anti-loosening and shock absorption. Anchor bolts: Anchor bolts are used to fix the tower of the wind turbine on the foundation to ensure the stability of the tower.

Anchor bolts usually need to possess properties like high strength and pull-out resistance. Stud bolts: Stud bolts are bolts with threads at both ends and are often used to connect two components that need to be fastened.

In wind turbines, stud bolts are usually used to connect components such as blades and hubs.

To ensure the safe operation of wind turbines, these fasteners usually need to possess properties like high strength, anti-fatigue and corrosion resistance, and they also need to be inspected and maintained regularly to ensure their fastening performance and safety. Meanwhile, with the continuous development of wind turbine technology, higher requirements have been put forward for the performance and quality of fasteners, such as higher strength, better corrosion resistance and lighter weight.

Therefore, fastener manufacturers are also constantly researching and developing and launching new types of fastener products to meet the needs of the wind turbine industry.

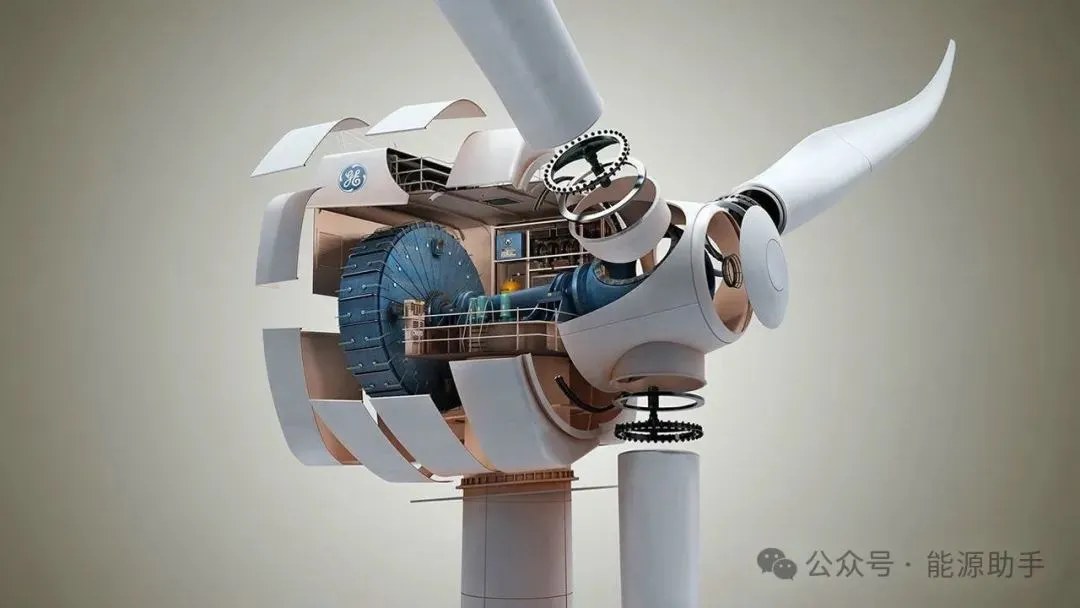

Fasteners in wind turbines mainly include bolts, nuts, washers and so on. These fasteners play roles in connecting, fastening and supporting various components of wind turbines.

The following are some common types of fasteners: Bolts: Bolts are one of the most commonly used fasteners in wind turbines and are used to connect components such as blades, towers, and nacelles. Bolts usually need to possess properties like high strength, anti-fatigue and corrosion resistance to ensure the safe operation of wind turbines in harsh environments.

Nuts: Nuts are used in conjunction with bolts to fasten connected components.

In wind turbines, nuts usually need to have functions like anti-loosening and self-locking to prevent bolts from loosening under the influence of vibration and wind force.

Washers: Washers are usually used to increase the contact area of bolt connections, disperse pressure and prevent the wear of component surfaces.

In wind turbines, washers can also play roles such as anti-loosening and shock absorption. Anchor bolts: Anchor bolts are used to fix the tower of the wind turbine on the foundation to ensure the stability of the tower.

Anchor bolts usually need to possess properties like high strength and pull-out resistance. Stud bolts: Stud bolts are bolts with threads at both ends and are often used to connect two components that need to be fastened.

In wind turbines, stud bolts are usually used to connect components such as blades and hubs.

To ensure the safe operation of wind turbines, these fasteners usually need to possess properties like high strength, anti-fatigue and corrosion resistance, and they also need to be inspected and maintained regularly to ensure their fastening performance and safety. Meanwhile, with the continuous development of wind turbine technology, higher requirements have been put forward for the performance and quality of fasteners, such as higher strength, better corrosion resistance and lighter weight.

Therefore, fastener manufacturers are also constantly researching and developing and launching new types of fastener products to meet the needs of the wind turbine industry.